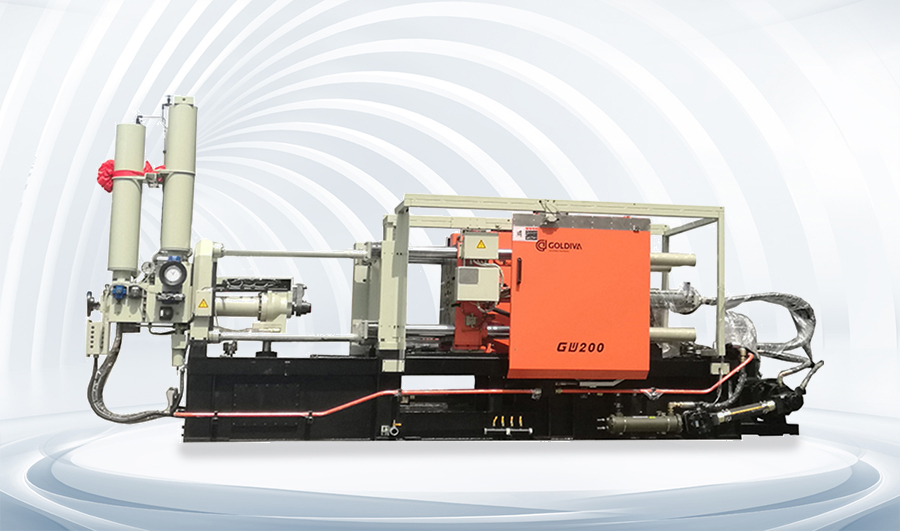

GW300Z New generation high-speed die-casting machine for ultra-thin aluminum and magnesium alloy parts Introduction

GoodWe GW300Z ultra-thin die-casting high-speed cold chamber die-casting machine is a special model developed for die-casting of ultra-thin aluminum-magnesium alloy parts. It is designed to meet the needs of ultra-thin die-casting in the 3C industry and other high-end fields, such as mobile phone mid-plate die-casting markets. This model is based on Japanese standards and the configuration requirements of magnesium alloy die-casting as standard. The production efficiency, injection performance, stability, and accuracy of this model are all in a leading position in China.

New generation of aluminum and magnesium alloy ultra-thin parts die-casting high-speed machine: GW300Z

1. High-performance dynamic response, fast running speed, the shortest cycle from mold opening to completion of dry cycle is about 6.7S, and the production efficiency is increased by 10%~15%.

2. With precise slope control, the proportional valve output decreases linearly, and the mold opening, closing and stopping at any position are smoother and more accurate. The repeatability is within 1mm, and the efficiency is further improved, which is at the leading level in China.

3. Excellent injection performance

※ Air injection speed can reach 11.5 m/s

※ Fast injection speed is stable, the speed difference after 100 cycles is ΔV≤0.04m/s

※ The injection acceleration is high. When the air injection is performed, the acceleration is 62g.

※ The injection pressure has high repetitive accuracy, and the pressure difference after 100 cycles is ΔP≤0.3bar

※ Injection stroke and follow-up stroke are adjustable within the range of 0-50mm

4. Simple integrated oil circuit design greatly reduces pressure loss and impact, and improves stability; the heat generated by the hydraulic oil is reduced, and the oil temperature is reduced by 5°C~8°C, which helps to extend the service life of the oil valve and seals and reduce the amount of cooling water.

5. The computer system touch screen adopts a flat design, the human-machine interface is humanized, parameter management is simplified, responsibilities are clearly defined, and it is easy to use, which greatly improves the efficiency of parameter search and management.

6. The electric box adopts strong and weak current isolation design to reduce electromagnetic interference and temperature drift, improve equipment safety, enhance system stability and ensure accuracy.

7. The vane pump adopts a special double-lip blade structure, which can withstand higher peak pressure, has stronger anti-pollution ability and longer service life.